BUSINESS UNITS

Press production

The cold sheet metal pressing department is aimed at the Automotive - Road Transport - Home Appliances - Air conditioning sectors. Boasting a fleet of 14 presses with tonnages from 500 to 1200 tons served by coil lines and 6-axis robots, the department is able to guarantee competitiveness and quality. Thanks to the internal maintenance of the tool dies and machinery we can also guarantee total production reliability.

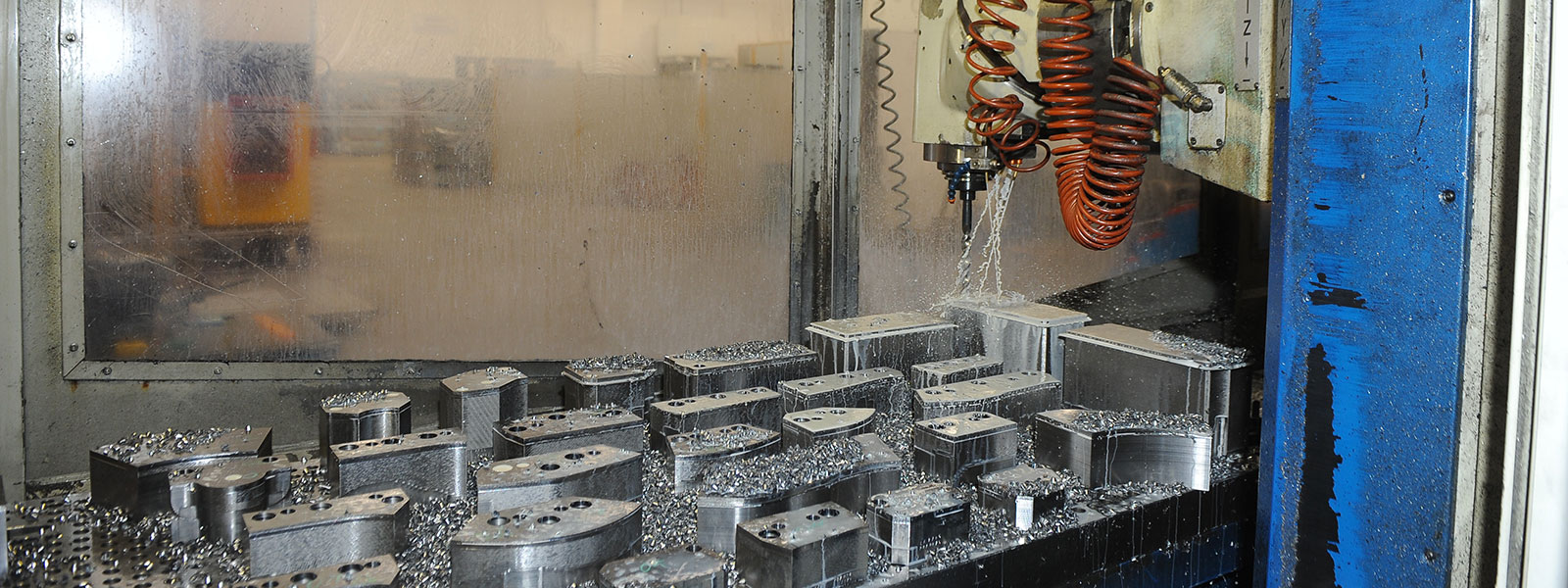

Milling & tool die construction

The potential of the milling and tool die construction department is given by the wide availability of CNC milling machines ranging from 2 m up to 8 m longitudinal travel. Thanks to the skills of our operators and high-quality machinery which are mostly equipped with automatic tool change and Fast Mill system, they allow us the feasibility of all types of processes in the field of tool die construction and assembly equipment. The tool die assembly department is equipped with fine grinding machines, industrial drills and tool die testing presses.

Production milling

Thanks to the processes that are tailor-made by our engineers and our milling machines equipped with tool magazines, SPL INDUSTRIES is able to carry out mass mechanical processes which are characterized by efficient and qualitatively reliable programming.

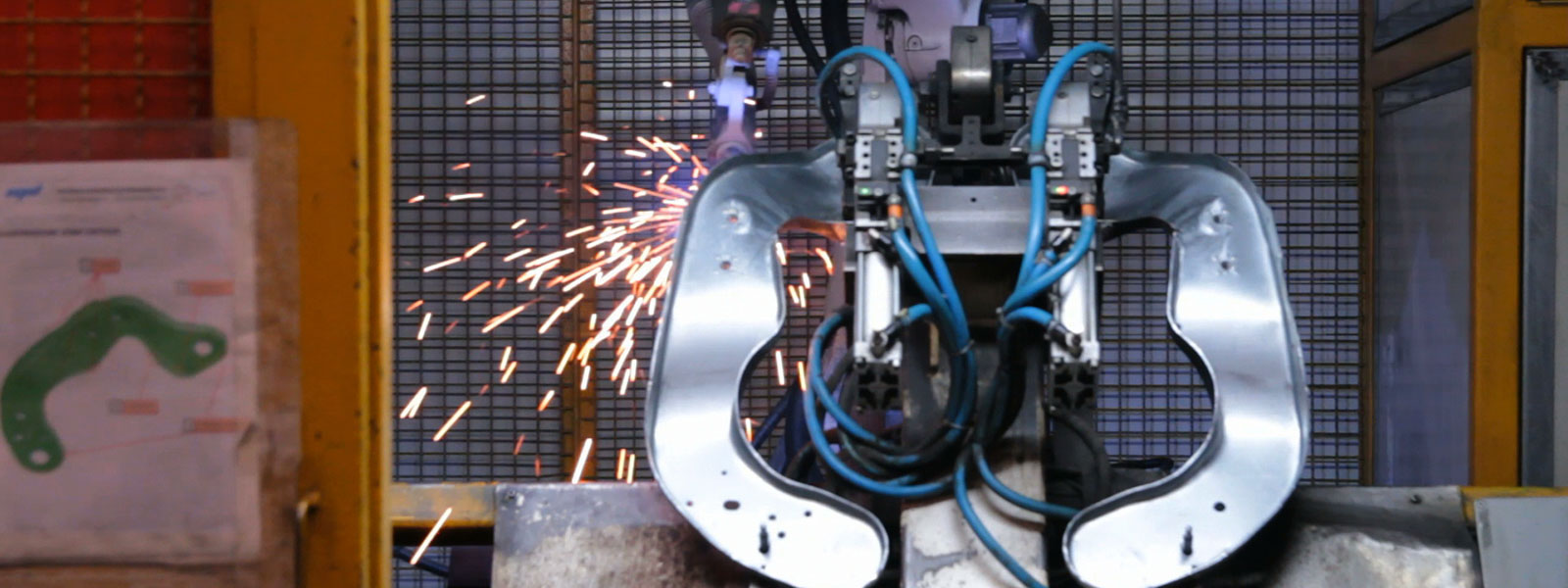

Body-in-white

The BIW department is equipped with CO2 welding robots, TIG and MIG welders, manual and CNC spot welders. The processes are carried out by highly qualified personnel and we are able to certify our welding’s.

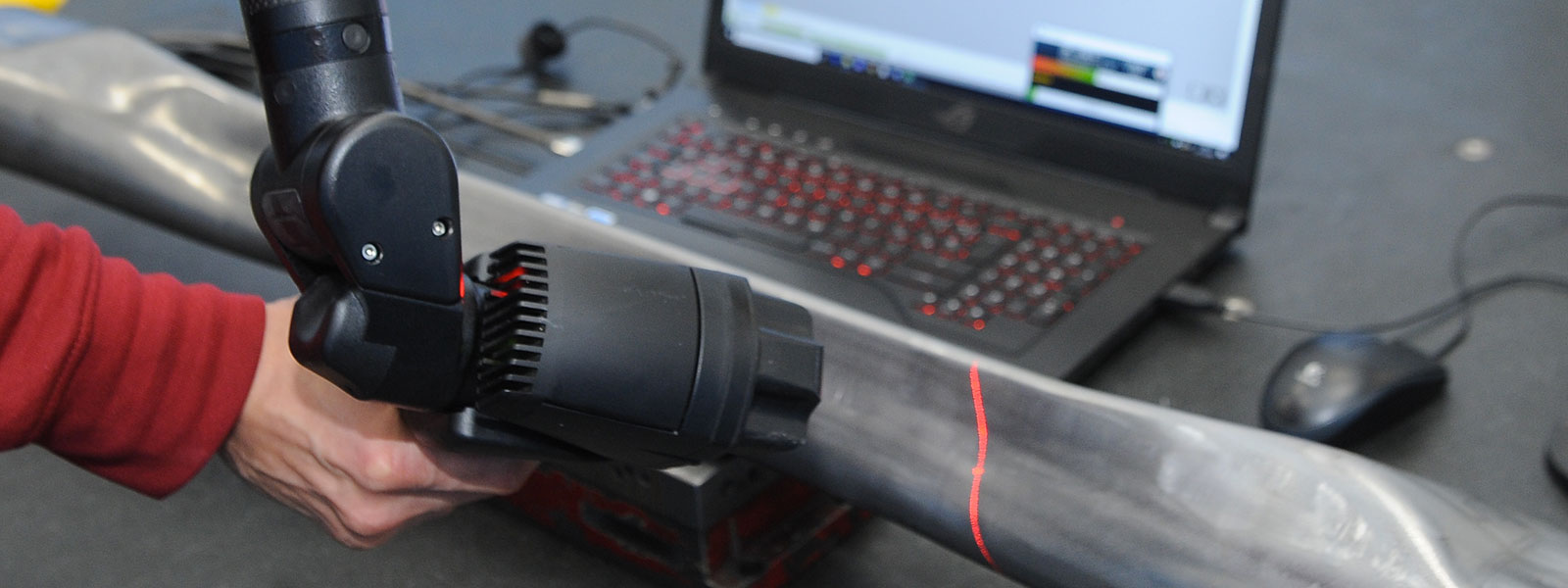

Quality laboratory

In the current market the Quality factor occupies a primary place. SPL Industries is equipped with latest generation measuring machines and laser scanners in order to easily carry out a wide range of measurements and surveys. Furthermore, all our production processes are set up according to the ISO 9001 and IATF 16949 certification criteria.

Tool die assembly and maintenance

This department is well equipped with tools and skills to intervene promptly on all maintenance problems regarding tool dies, systems and machinery; it also takes care of the assembly and testing of the equipment.

Engineering Development

From a know-how gained over the years and from the direct contact with the production department, as well as with the aid of cutting-edge 3D programs, our Technical Office is able to carry out the design for tool dies, assembly equipment and control gauges studied down to the smallest details by applying a meticulous process characterized by over 300 checks.

Warehouse

The logistics team has the primary task of managing the finished product and the incoming raw material, it also carries out specific checks in the acceptance of arrivals, management of ''Just in Time'' deliveries and management of the warehouse with ''First in - First out'' rotation.

Certifications

look at our certifications

Company policy

Quality policy

’

Recognitions

Some of our recognitions