The management of health and safety at the workplace, commonly referred to as occupational safety, concerns all the preventive and protection measures to be adopted to better manage the health, safety and welfare of workers, in order to avoid or minimising as much as possible the exposure of workers to work-related risks, reducing or eliminating occupational accidents and illnesses.

For the reasons given above, we at SPL INDUSTRIES have always been concerned about the safety issue, that is why, over the years, we have been adopting many solutions. Here follow some of them:

a) Management of all the user and maintenance manuals of our machines; this allowed us to create a scheduler with all the checks and audits to be preventively done in order to have an always efficient machine from a production and safety point of view.

b) We created an archive with the data sheets of the chemical products that we use.

c) We inserted safety posters and road system signage both inside our plant and in the external courtyards of the company.

d) Next to each machine, we hung some operational instructions related to the safe use and we also delivered them by hand to each operator.

e) We realized external cages (with base in reinforced concrete and REI non-flammable walls), where we keep any potentially flammable material such as oils, chemical products or gas bottles. Moreover, the fuel tank has been moved outside.

f) We created a water network to extinguish possible fires and realized two emergency exits in the scrap recovery tunnel under the presses.

g) We realized a new external recharge area for forklifts, preventing the inhalation of fumes and noxious condensation.

h) The line of N° 6 robotic presses, in addition to press N°7 and press N°10, have been interdicted by a special fence, as well as all the milling machines of the mold construction department, thus avoiding possible accidents of the operators who may inadvertently be inside the working area of the machines.

i) We are periodically carrying out the "state-region agreement" training course for new employees, according to a scheduled program.

l) Photocells have been installed on the main machines (presses, welding cells and milling machines), so the machine will not start if it detects the operator's presence.

m) We periodically carry out a training to the whole personnel about safety measures and related verification tests.

n) Finally, we adhered to the Codes of conduct related to 45001, 231 and the historic 626 certifications.

o) The company has started a re-paving operation with resin of the whole structure distinguishing with different colors the work areas, the transit areas for fork-lifts trucks and the related pedestrian areas.

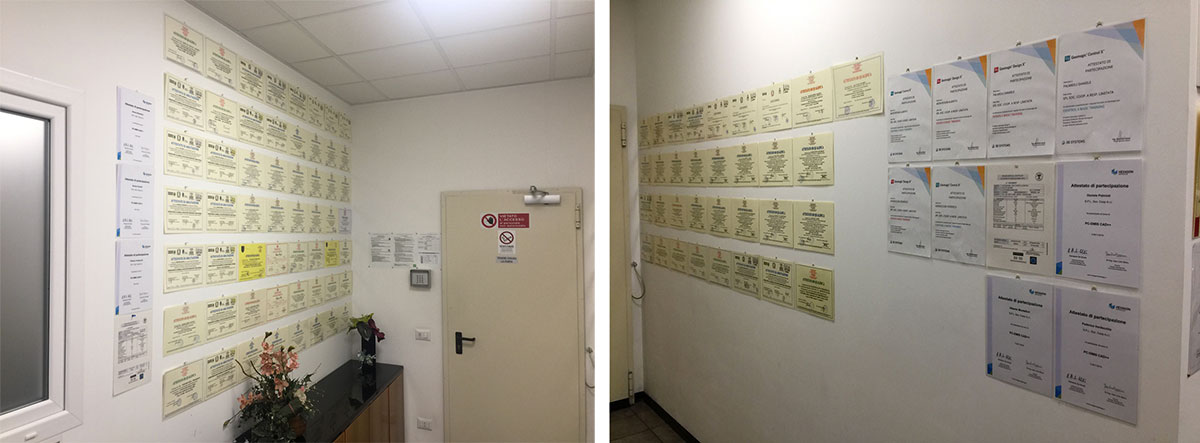

p) The company regularized its position making its employees attend all the courses according to the current legal dispositions, as shown in the panorama pictures.